About us

The Department of Mechanical Engineering is part of KIT's Area 3 "Mechanical and Electrical Engineering" together with the Department of Electrical Engineering and Information Technology, four Helmholtz programs, and eight institutes of the large-scale research area. The department consists of more than 20 institutes with about 1,000 employees, including about 40 professors, 460 scientific employees, and 200 employees in administration and technology. In addition, there are several hundred tutors and scientific assistants.

In the 2025 edition of the "QS World University Rankings by Subject", which was published on Wednesday, March 12, 2025, the Karlsruhe Institute of Technology (KIT) achieves excellent results in its central subject areas. In the "Natural Sciences" it is ranked 36th, in the "Engineering Sciences" 53rd worldwide. In a national comparison, this puts KIT in second and third place in these subject groups.

In the field of natural sciences, KIT is among the top 50 worldwide with the single subject of materials science (25th place). [...]

The best rankings in the engineering sciences are achieved by KIT with chemical engineering (25th), mechanical engineering (45th) and petroleum engineering (19th).

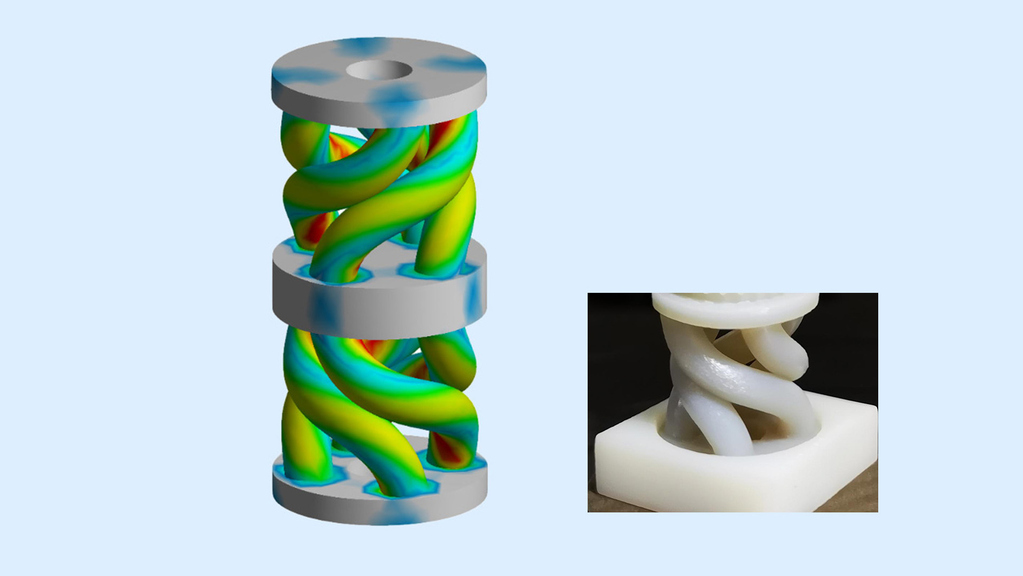

An international team of researchers coordinated at the Karlsruhe Institute of Technology (KIT) has developed mechanical metamaterials with a high elastic energy density. Thanks to highly twisted rods that deform in a spiral shape, they have a high degree of rigidity and can absorb and release large amounts of elastic energy. The researchers confirmed their initially theoretical results with simple pressure experiments. They report their findings in the journal Nature. (DOI: 10.1038/s41586-025-08658-z)[...] "The difficulty lies in combining contradictory properties: high stiffness and large recoverable deformation with limited strength," says Prof. Peter Gumbsch from the Institute for Applied Materials (IAM).

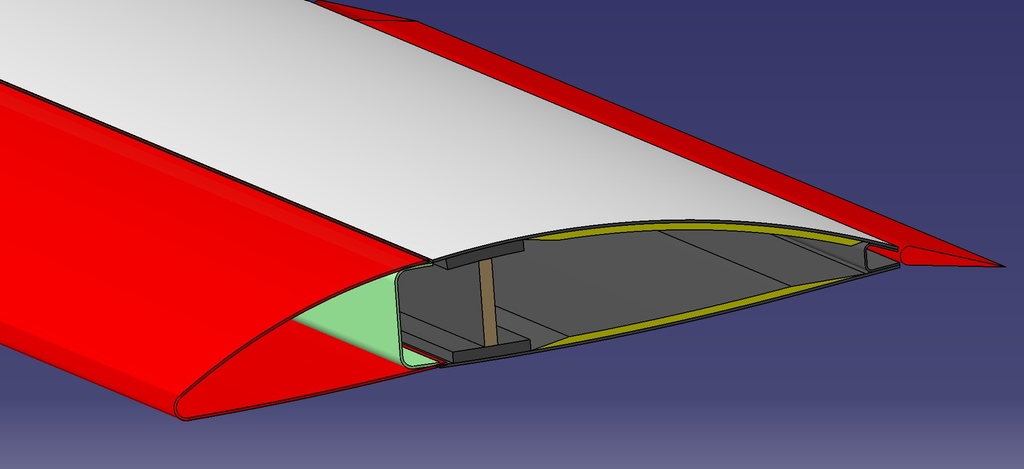

The Akaflieg is delighted to have received funding of just under €300,000 as part of the "Zukunftsoffensive Luft- und Raumfahrt-Nachwuchs für Baden-Württemberg" program. This program supports student groups that contribute to the further development of aerospace through innovative projects and inspire young talent for the field.

The Akaflieg is a student group that has been involved in the development, construction and testing of innovative gliders for decades. Through practical research projects, students gain valuable experience in the fields of aerodynamics, structural mechanics and production engineering. AKflieg press release.

Further information can be found at vorstand@akaflieg-karlsruhe.de or on the website akaflieg-karlsruhe.de

As the highlight of the winter semester, the KIT Department of Mechanical Engineering celebrated its Department Festival Colloquium on 14.02.2025 in the Tulla lecture hall in Building 11.40. The keynote speech was given by Prof. Dr.-Ing. Martin Cichon from the FAST Institute of Railway Systems with the title "Redtenbacher - or why the railroad can't go straight ahead". In this festive setting, this year's Manfred Hirschvogel Prize for the best dissertation in the field of mechanical engineering / economics with innovative, trend-setting results for practice and research was awarded to Dr. Michael Baranowski. The prize for student commitment went to Clara Lickert from the MACH/CIW student council.

Impressions and the joint "cap picture" of all graduates can be found in our picture gallery.

According to estimates by the Federal Environment Agency, at least 100,000 tons of tire abrasion are produced annually in Germany when tires come into contact with the road surface. This corresponds to around a third of the microplastic emissions released annually in Germany. Due to their higher weight, vehicles with electric drives often cause more tire abrasion than those with combustion engines. Researchers at the Karlsruhe Institute of Technology (KIT) and the Fraunhofer Institute for Industrial Mathematics are investigating the amount of abrasion caused by electrified vehicles in the RAMUS project (which stands for: tire abrasion measurement and simulation). In order to develop a prediction model for tire wear, they are testing tires on a test bench in operating cycles that represent real usage behavior in a condensed form.

The annual Professors' Café for first-year students of Mechanical Engineering, Mechatronics and Materials Science and Engineering is taking place today in the "Festsaal of the Studierendenwerk" (located between the Mensa and Bib on Adenauerring). Professors, the student council and the InSL staff (Information and Services for students) will be there to answer all your questions about starting your studies. There will also be good coffee and delicious cookies - even for last-minute visitors.

The doors are open until 1:00 pm.

Directions to the Festsaal of the Studierendenwerk

more News